Services

System Design and Modeling

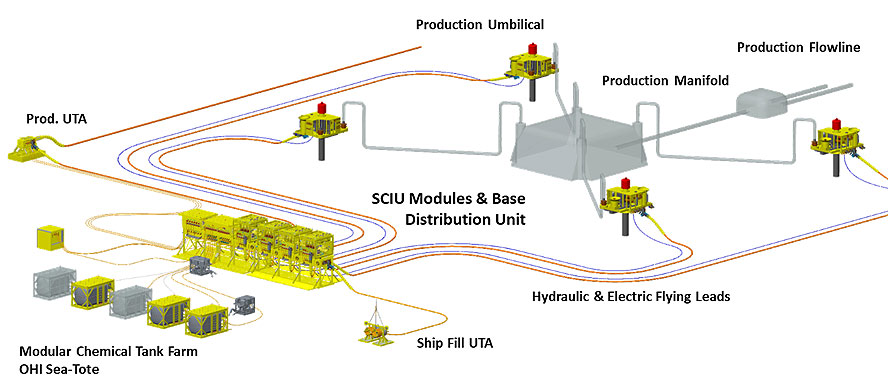

The key to OHI's subsea chemical injection systems is a seamless incorporation of operation and reliability along with operator interface. The approach has utilized a great amount of known and field proven technology, while adapting high reliability surface proven equipment with industry know marinizing techniques to provide a reliable and practical subsea system.

OHI has experience with most all offshore chemical well dosing treatment protocols used for flow assurance. Whether the system requires methanol batching or dosing for paraffin, corrosion, and scale, or to include additives for greater well performance, OHI has incorporated each specific characteristic of these fluids into the design of the system.

The result of accessing OHI experience, is an overall system that optimizes specific field characteristics and can generate an approach and design where cost, operations, reliability, and operator interfaces are considered and integrated.

Economic Analysis

OHI can perform a detailed CAPEX and OPEX analysis where this new architecture is incorporated. CAPEX considerations are cost of conventional systems, reduction of umbilical, reduction of installation, reduction of surface platform footprint. OHI can also assist in determining the costs of maintenance and operation, training, refilling operations, and refurbishing and reusing the components.

Systems Engineering and Analysis

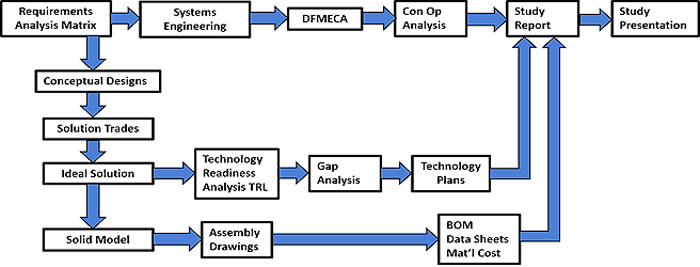

OHI can provide detailed systems definition, optimization, and configuration study utilizing industry recognized tools and techniques including specifications analysis, Design Failure Modes and Affects, Hazardous Operations Analysis, Technology Readiness and Risk Analysis, and Programming Analysis, to provide a complete and disciplined approach to the system.

OHI can provide detailed systems definition, optimization, and configuration study utilizing industry recognized tools and techniques including specifications analysis, Design Failure Modes and Affects, Hazardous Operations Analysis, Technology Readiness and Risk Analysis, and Programming Analysis, to provide a complete and disciplined approach to the system.